AUTOOL CT500 6-Cylinder Ultrasonic Fuel Injector Cleaner & Tester, GDI/EFI/FSI Compatible, 2000ml Tank, 70W, 12V/70V/120V

R19,900.00 Original price was: R19,900.00.R15,900.00Current price is: R15,900.00. incl. VATR17,304.35 Original price was: R17,304.35.R13,826.09Current price is: R13,826.09. excl. VAT

Out of stock

Available 'Buy Now Pay Later' Options

R658.08 x 36 payments

Available 'Buy Now Pay Later' Options

R658.08 x 36 payments

Delivery anywhere is SA

Once we receive payment for your order, delivery updates will be sent via email to keep you updated.

Collection Points

Visit our offices in Isando, Kempton Park.

Our work hours are from 8am-5pm.

The AUTOOL CT500 is a professional-grade fuel injector cleaning and testing solution that combines ultrasonic cleaning with micro-computer oil pressure control. By simulating real-world engine conditions, it ensures accurate assessment of injector performance for a variety of vehicles—whether GDI, EFI, FSI, or standard injectors. Built with a 6-cylinder design, a large 2000ml ultrasonic cleaning tank, and a smart control panel, the CT500 delivers powerful cleaning and thorough diagnostics for automotive workshops, research labs, and training programs.

📥 Download the AUTOOL CT500 Manual

Key Features

1. Wide Range of Supported Injectors

- Multi-Type Compatibility: Works seamlessly with GDI, EFI, FSI, and standard fuel injectors.

- Flexible Voltages: Three selectable voltage options (12V, 70V, 120V) accommodate injectors from European, American, and Asian vehicles.

- Comprehensive Cleaning & Testing: Supports both cleaning and testing of standard and GDI injectors, including those from Mercedes-Benz, BMW, Audi, Porsche, Ford, and other direct-injection engines.

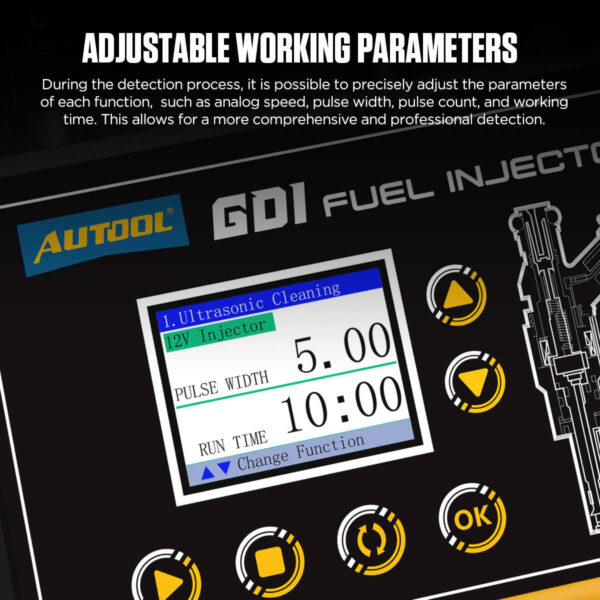

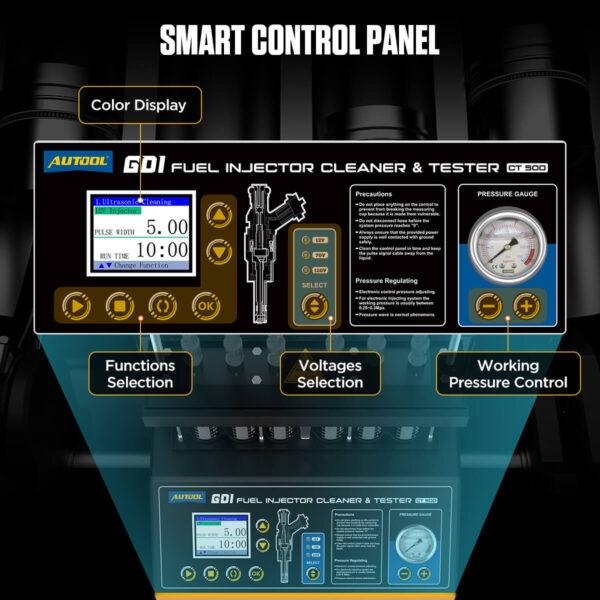

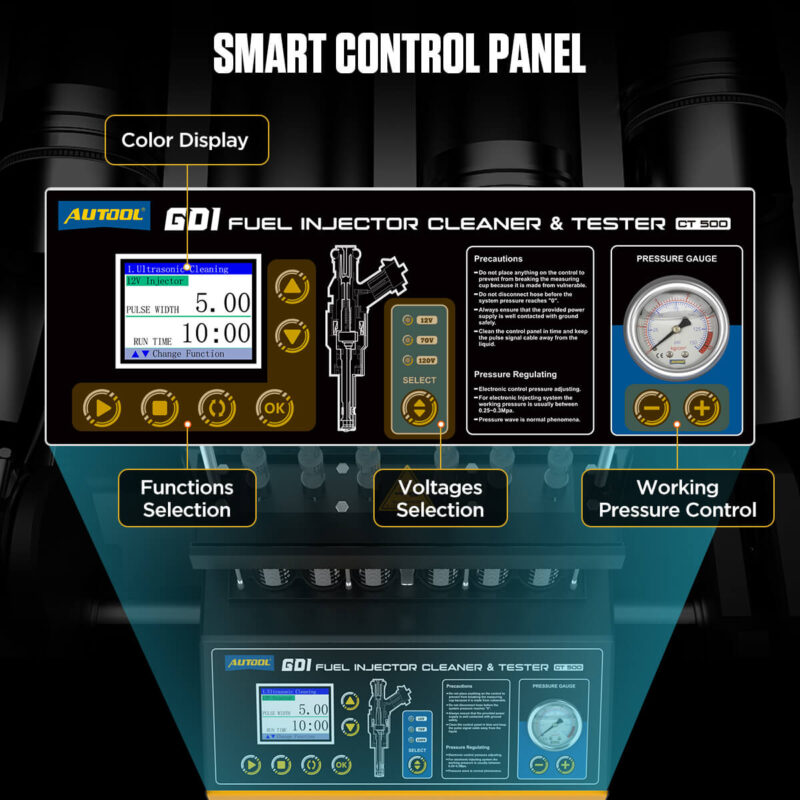

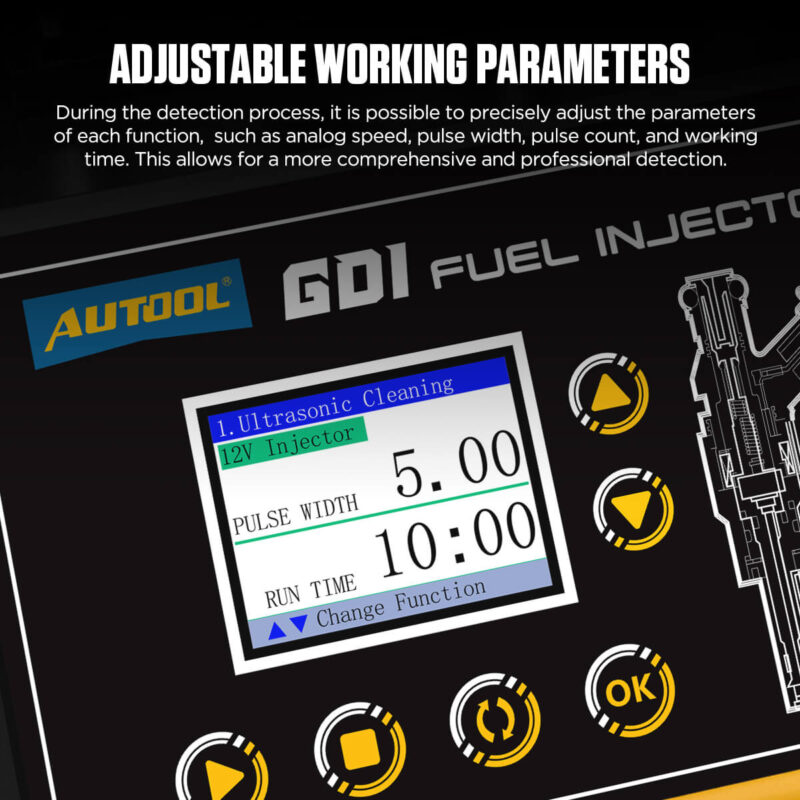

2. Smart Control Panel & Adjustable Parameters

- High-Definition Color Display: Offers clear, intuitive navigation of functions.

- Function Selection: Easily choose between ultrasonic cleaning, various test modes, and more.

- Voltage Settings: Adapt injector voltage (12V/70V/120V) for precise, damage-free testing.

- Working Pressure Control: Wide-range electronic regulator ensures stable oil pressure.

- Customizable Testing: Adjust analog speed (0–7500rpm), pulse width (0–40ms), pulse count, and run time (0–10min) for thorough diagnostics.

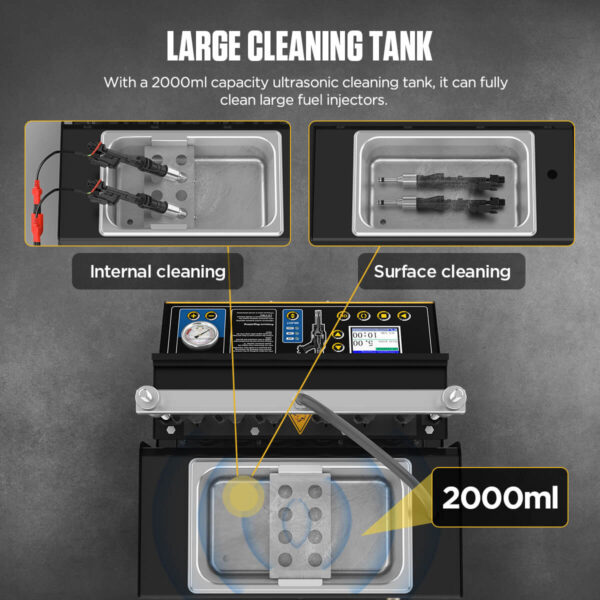

3. Advanced Ultrasonic Cleaning (70W)

- Large 2000ml Tank: Spacious ultrasonic cleaning chamber for both internal and surface cleaning of large or multiple injectors.

- High-Power Output: 70W ultrasonic power paired with a built-in cooling fan and thermal protection for consistent, efficient cleaning.

- Simultaneous Cleaning: Clean up to six injectors at once, saving time and improving workflow.

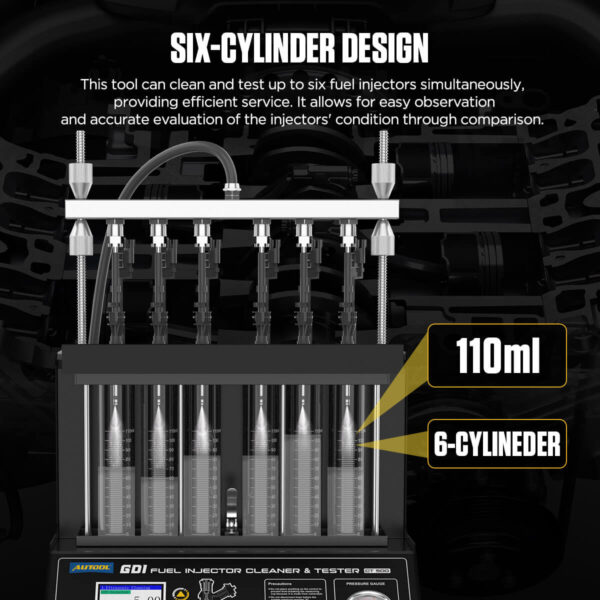

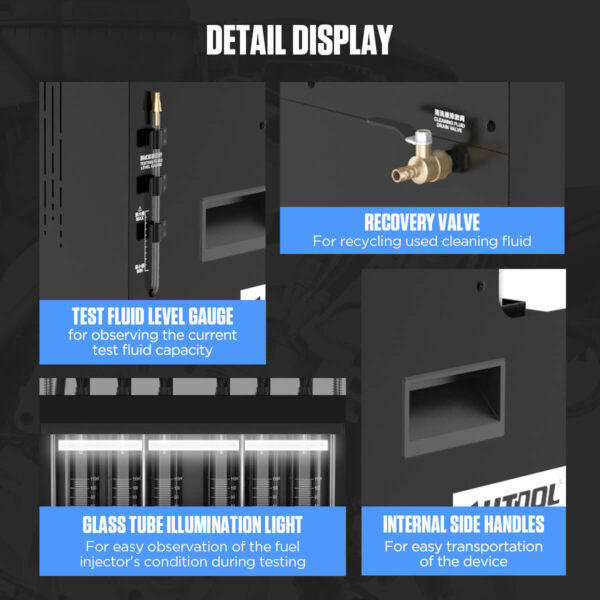

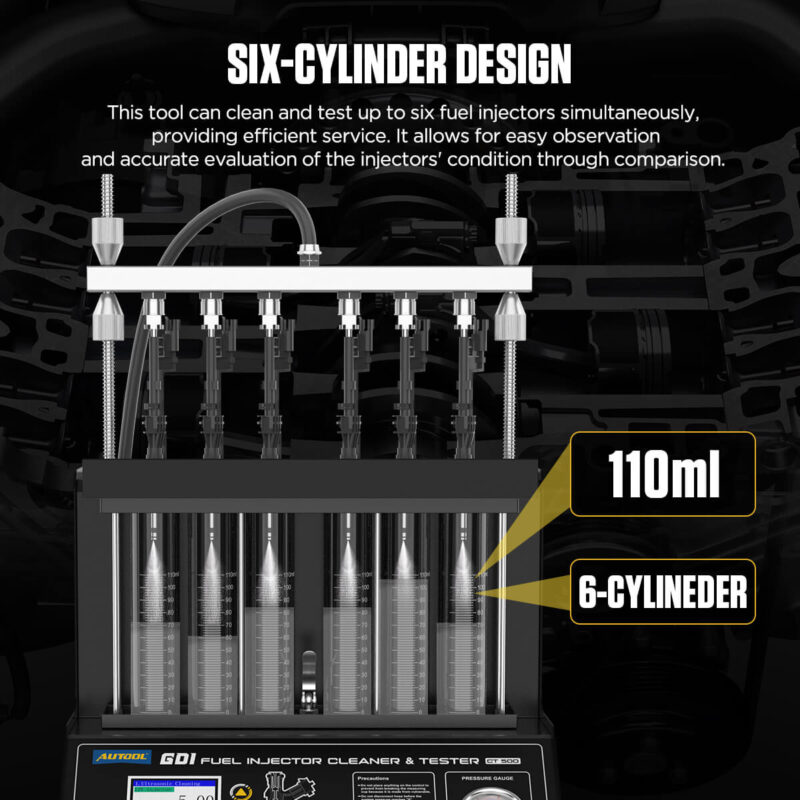

4. Six-Cylinder & Dual Drain Design

- Test Six Injectors at Once: Compare spray patterns, flow rates, and performance across cylinders simultaneously.

- Two Control Valves: Streamlines test-fluid disposal and recovery, enabling repeated fluid use and minimizing waste.

5. Protective Guard & Safe Operation

- Oil Spray Prevention: A dedicated protective guard helps contain accidental fluid discharge from unsealed injectors during testing.

- Component Protection: Shields critical parts—like glass measuring cylinders and the control panel—from potential damage.

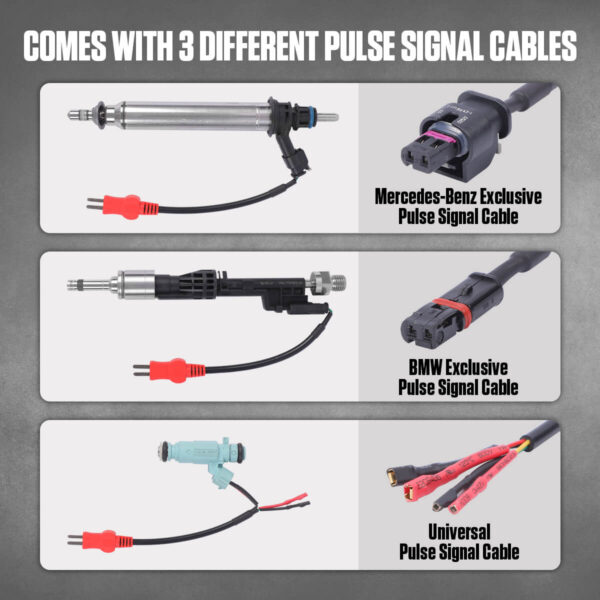

6. Comes with Three Pulse Signal Cables

- Mercedes-Benz Exclusive Pulse Signal Cable

- BMW Exclusive Pulse Signal Cable

- Universal Pulse Signal Cable

These specialized cables ensure accurate signal transmission for specific GDI injectors while maintaining broad compatibility with standard injectors.

7. Practical Storage Drawer

- Organized Compartments: A built-in drawer provides labeled sections to store adapters, fittings, and accessories, preventing misplacement.

8. Three-Year Warranty

- Extended Coverage: Protects against non-human-factor damage, with free replacement parts available for up to three years.

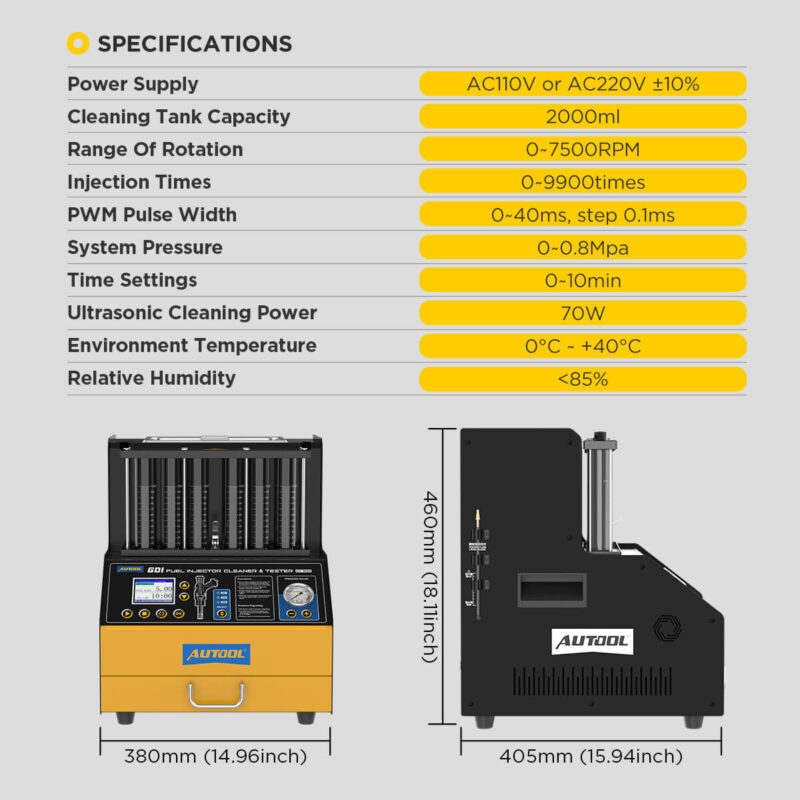

Specifications

| Item | Specification |

|---|---|

| Power Supply | AC110V or AC220V (±10%) |

| Cleaning Tank Capacity | 2000ml |

| Ultrasonic Cleaning Power | 70W |

| Simulated RPM Range | 0–7500rpm |

| Injection Times | 0–9900 times |

| PWM Pulse Width | 0–40ms (0.1ms increments) |

| System Pressure | 0–0.8MPa |

| Time Settings | 0–10min |

| Supported Cylinders | 6 |

| Dimensions (W×D×H) | 380×405×460 mm (14.96×15.94×18.11 in) |

| Relative Humidity | <85% |

| Operating Temperature | 0°C to +40°C |

| Compatible Voltages | 12V, 70V, 120V |

Warm Tips & Fluid Recommendations

- Professional Cleaning & Test Fluids:

- Use a dedicated test fluid that is colorless, odorless, and non-corrosive for performance checks.

- Use a professional injector ultrasonic cleaning fluid for effective carbon deposit removal.

- If these are unavailable, 75%+ medical alcohol may be used as an alternative, but with reduced effectiveness.

- Avoid Corrosive Fluids for Testing:

- Corrosive cleaning solutions can harm the machine’s internal components. Any damages caused by improper fluid use may void free repair services.

- Never Run Dry:

- Always add enough cleaning fluid before starting the ultrasonic cleaning function. Operating it “dry” can damage the ultrasonic motherboard.

CT500 Ultrasonic Fuel Injector Cleaner Functions

-

Ultrasonic Cleaning

- Uses high-frequency vibration and pulse signals to remove internal carbon and deposits from injectors.

-

No-Disassembly Cleaning

- An additional function (requiring special adapters) that cleans injectors in-situ without dismantling them from the engine.

-

Reverse Flushing

- Flushes test fluid from the injector outlet back to the inlet (top fuel supply injectors only), helping dislodge dirt or blockages from the injector or its strainer.

-

Multiple Test Modes

- Idle Speed Test (0–20ms): Simulates engine idling to assess injector function.

- Medium Speed Test (0–7.5ms): Mimics mid-range RPM performance.

- High-Speed Test (0–4ms): Replicates high RPM operation.

- Acceleration Test: Checks injector response under rapid RPM changes.

- Variable Speed Test: Evaluates injector performance through fluctuating RPM.

- Leak Test: Measures seal integrity under system pressure.

- Idle-Speed Sprayability Test: Observes spray pattern at idle.

- Medium-Speed Sprayability Test: Verifies fuel mist consistency at mid-range RPM.

- High-Speed Sprayability Test: Confirms spray performance at higher RPM.

- Flow Balance Test: Compares volumetric flow among all injectors at various speeds.

- Observation of Fuel Injection Shape: Checks uniformity of spray angles and patterns across injectors.

- Leak Detection Test: Specifically checks tightness of the injector needle valve under high pressure.

Frequently Asked Questions

-

Can diesel injectors be cleaned and tested with AUTOOL CT series products?

- Cleaning: Yes, diesel injectors can be cleaned in the ultrasonic bath.

- Testing: No, the CT series does not support diesel injector testing.

-

How Do I Set the Test Parameters?

- Choose your function, set the test duration (0–10min), and let the smart control panel handle the rest—no special calibration required.

-

Why Not Use Cleaning Fluid for Testing?

- Testing fluid must be non-corrosive to protect machine parts. Cleaning fluid can damage seals and internal mechanisms.

-

How to Choose Voltage for GDI Injectors?

- Start at 12V, then gradually move to 70V or 120V. If injectors fail to respond, quickly adjust to the recommended voltage to prevent damage.

-

Will the Wrong Voltage Damage GDI Injectors?

- Brief exposure to incorrect voltage typically won’t cause immediate harm. Prolonged high voltage, however, can degrade injector components over time.

-

How do I choose a cleaning fluid?

- A dedicated, highly corrosive injector cleaning fluid is recommended for removing deposits.

- 75%+ medical alcohol can be used as a less effective fallback option.

- Avoid using cleaning fluid for testing to prevent internal damage.

Package Includes:

1pc CT500 Fuel Injector Machine

1pc Cleaning Fluid Drain Valve

1pc Ultrasonic bath cover

1pc Oil rail

6pcs Nozzle pads

6pcs Sealing Ring

5pcs Plugs for oil rail

1pc Funnel

4pcs Fixing Bolts

4pcs Ultrasonic Cleaning Brackets

1pc Pulse Signal Cable

1pc Power Cable

6pcs Adapt Cables

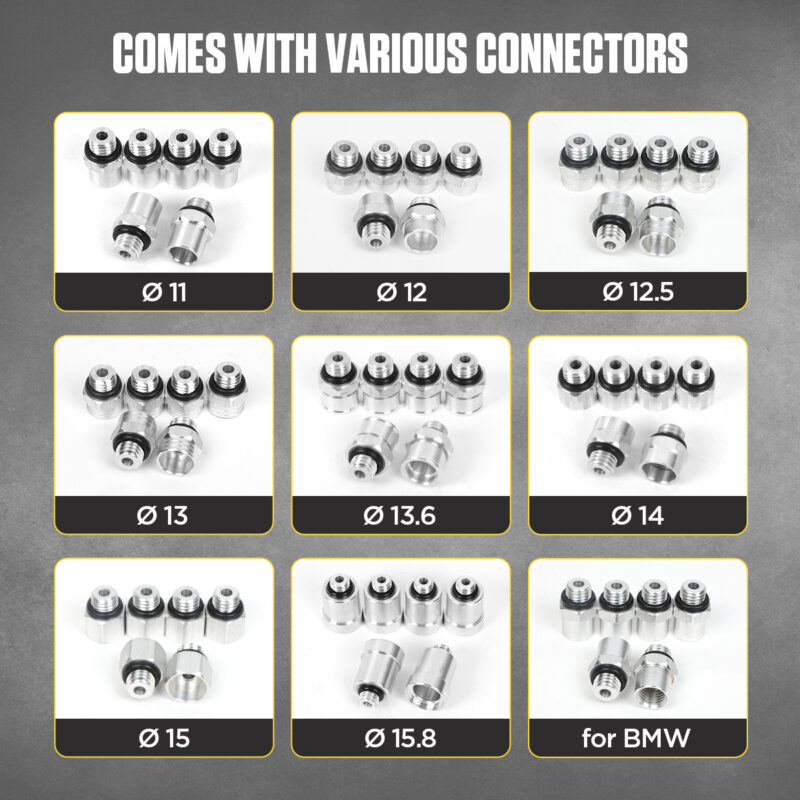

6pcs 11mm adapters

6pcs 12mm adapters

6pcs 12.5mm adapters

6pcs 13mm adapters

6pcs 13.6mm adapters

6pcs 14mm adapters

6pcs 15mm adapters

6pcs 15.8mm adapters

6pcs Fit For BMW special adapters

1pc User manual with warranty card

Final Notes

- The AUTOOL CT500 delivers a comprehensive, professional solution for diagnosing, cleaning, and revitalizing your vehicle’s fuel injectors.

- With ultrasonic cleaning, adjustable voltages, and versatile test modes, it significantly improves injector performance, reduces emissions, and enhances engine efficiency.

- For repair shops, performance tuners, and automotive educators, this system is an essential investment—backed by a 3-year warranty for non-human-factor damage.

Upgrade your fuel injector maintenance routine with the AUTOOL CT500—and experience cleaner, more efficient engine performance today.

| Weight | 16 kg |

|---|---|

| Dimensions | 40 × 42 × 48 cm |

| Category ID | pdi |

| Sales Rep | salesrep3 |